Introduction

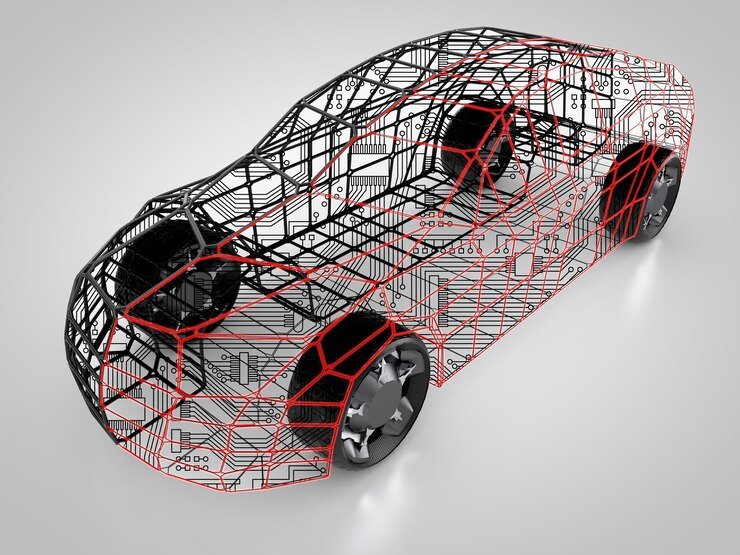

Rising 3D printing technology allows hobbyists, modelers, and automotive aficionados to make incredibly detailed passenger car models right from their homes. 3D printing passenger cars provides countless opportunities whether your design is for a collection, prototyping new vehicle designs, or building instructional models.

In this guide, we’ll explore the best methods, tools, and resources to make high-quality passenger car models for 3D printing. You’ll also find tips for designing, printing, and finishing your models, along with the best sources for free and paid STL files.

Why 3D Print Passenger Car Models?

1. Customization & Personalization

Customizing car models with various colors, sizes, and additions to fit future designs or real-life vehicles is made possible with 3D printing.

2. Reasonably priced prototyping and model building

3D printing lets you produce automotive models at a fraction of the cost instead of pricey die-cast versions.

3. Educational & Engineering Applications

Car models can be used in mechanical engineering, aerodynamics studies, and automotive design training.

4. Fun & Collectible

3D printing allows enthusiasts to recreate classic cars, concept cars, and futuristic vehicles for display and collection.

How to Make Passenger Car Models for 3D Printing

1. Finding 3D Car Model Files (STL & OBJ Formats)

Before printing, you need a high-quality STL file of your desired car model. Here’s where to find them:

Free 3D Model Sources:

- Thingiverse – Community-driven platform offering free passenger car models.

- GrabCAD – Engineering-based platform with detailed car models.

- Printables – A growing 3D printing repository with high-quality car models.

- Free3D – Features various scale models and car body parts.

Premium 3D Model Sources:

- CGTrader – Offers highly detailed paid car models.

- TurboSquid – Professional-grade realistic car models.

- MyMiniFactory – Verified files for high-quality prints.

- Cults3D – Independent designers selling unique car models.

2. Choosing the Right 3D Printing Technology

The choice of 3D printing technology determines the detail, durability, and scale of your car model.

FDM (Fused Deposition Modeling) – Best for Large Models

- Pros: Affordable, widely available materials.

- Cons: Less detail compared to resin printing.

- Best Filaments: PLA (Easy to print), PETG (More durable), ABS (Heat-resistant).

SLA/DLP Resin Printing – Best for High Detail

- Pros: Ultra-fine details and smooth surfaces.

- Cons: More expensive, requires post-processing.

- Best Resins: Standard resin (for general use), ABS-like resin (for durability), Water-washable resin (for easy cleaning).

3. Setting Up Your 3D Model for Printing

Once you have your STL file, optimize it for 3D printing using slicing software like:

- Cura (Best for FDM printers).

- PrusaSlicer (Best for Prusa 3D printers).

- LycheeSlicer (Best for resin prints).

Key Settings for Best Results:

- Layer Height: 0.1mm (high detail), 0.2mm (faster prints).

- Infill: 15-30% (for lightweight display models).

- Supports: Yes, for overhanging parts like spoilers and side mirrors.

- Print Orientation: Print in multiple parts to reduce print time and improve detail.

4. Post-Processing & Finishing the Model

After printing, follow these steps for a professional-quality finish:

Sanding & Smoothing

- Use 400-1000 grit sandpaper to remove layer lines.

- Apply filler primer to create a smooth base.

Painting & Airbrushing

- Use acrylic or automotive spray paint for realistic finishes.

- Apply a clear coat for a glossy or matte look.

- Add custom decals for realism.

Assembling Multiple Parts

- Use super glue or epoxy resin for strong bonds.

- Align parts precisely using clamps or masking tape before gluing.

Adding Clear Windows & Lights

- Print transparent parts separately using clear resin or PETG.

- Install LEDs for realistic car headlights and taillights.

READ MORE – Kingdom Hearts Necklace 3D Print: How to Create the Perfect Fan Accessory

FAQs

1. Can I Sell 3D-Printed Car Models?

No, unless you have permission from the original designer or manufacturer. However, personal prints for display, cosplay, and gifts are allowed.

2. What’s the Best Scale for 3D-Printed Passenger Car Models?

- 1:24 Scale (Small, detailed, great for collections).

- 1:18 Scale (Larger, good for display models).

- 1:10 Scale (RC car enthusiasts and model builders).

3. How Long Does It Take to 3D Print a Car Model?

- Small models (1:24 scale): 4-8 hours.

- Medium models (1:18 scale): 12-24 hours.

- Large models (1:10 scale): 30+ hours.

4. What’s the Best Filament for Durable 3D-Printed Cars?

- PLA: Easy to print but brittle.

- PETG: Stronger and impact-resistant.

- ABS: Heat-resistant and durable but harder to print.

5. Can I Modify an Existing 3D Car Model?

Yes! Use Blender, Tinkercad, or Fusion 360 to edit designs, add logos, or modify car features before printing.

Conclusion

For amateurs, designers, and auto aficionados, developing passenger car models for 3D printing is a fascinating and fulfilling endeavor. 3D printing lets you realize your idea whether your preferred model is traditional, customized race automobile, or future vehicle.

Professional-quality automobile models that stand out can be created by using correct printing settings, post-processing methods, and material selections. Start looking at free and paid STL files, play around with finishes, and compile the best 3D-printed passenger car models!