Introduction

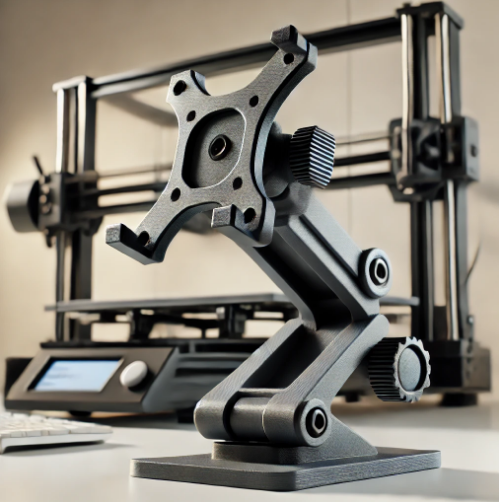

Functioning prints are becoming somewhat common in the realm of 3D printing. One such practical and adaptable print is a table mount, a tool meant to hold monitors, cameras, microphones, and more. 3D printing a table mount is a great approach to meet your needs whether they are space saving, ergonomic improvement, or unique mounting solution creation.

This guide will cover everything you need to know about table mount 3D printing, including design considerations, material selection, step-by-step instructions, and troubleshooting common issues.

Why 3D Print a Table Mount?

1. Cost-Effective and Customizable

Traditional table mounts can be expensive, and finding the perfect fit for a unique application is often difficult. 3D printing a custom table mount allows for complete customization at a fraction of the cost.

2. Ergonomic and Space-saving advantages

A well-made table mount can enhance ergonomic posture and assist you to clear your workstation. For monitor arms, microphone holders, or camera stands specifically, this is quite handy.

3. Durability and Strength

3D-printed table mounts can surprisingly be robust and long-lasting with the correct filament and print settings.

Selecting appropriate 3D printing materials

Making sure your table mount is robust, long-lasting, and able to bear weight depends on choosing the suitable filament.

1. PLA (Polylactic Acid)

- Pros: Easy to print, good dimensional accuracy

- Cons: Brittle and weak under heavy loads

2. PETG (Polyethylene Terephthalate Glycol)

- Pros: Strong, impact-resistant, slightly flexible

- Cons: Requires a heated bed and proper cooling settings

3. ABS (Acrylonitrile Butadiene Styrene)

- Pros: Heat-resistant, durable

- Cons: Prone to warping, requires an enclosed printer

4. Nylon

- Pros: High tensile strength, excellent durability

- Cons: Absorbs moisture, more challenging to print

For most applications, PETG is the best choice due to its balance between strength, flexibility, and ease of printing.

Designing a Table Mount for 3D Printing

1. Define the Purpose

Before designing, consider:

- What will the mount hold? (Monitor, microphone, camera, etc.)

- What weight does it need to support?

- How will it attach to the table? (Clamp, screws, adhesive?)

2. Use CAD Software

For creating a custom 3D model, software like Fusion 360, Tinkercad, or FreeCAD can help design a functional and precise table mount.

3. Consider Reinforcement and Stress Points

- Increase wall thickness for better strength

- Use fillets and chamfers to reduce stress concentration

- Add ribbing or structural supports for added durability

Best Printing Settings for a Table Mount

To ensure optimal print quality and strength, use these settings:

- Layer Height: 0.2mm for detail and strength balance

- Infill Density: 50%+ for added durability

- Wall Thickness: 3-4 walls for better structural integrity

- Print Speed: 40-60mm/s to prevent layer adhesion issues

- Supports: Enable supports for overhanging parts

Assembling and Installing a 3D-Printed Table Mount

Step 1: Post-Processing

- Sand rough edges for a clean finish

- Use acetone smoothing (for ABS) or epoxy resin for added durability

Step 2: Testing Fitment

Before installing, test the fit of all components to ensure a snug and secure assembly.

Step 3: Securing the Mount

- Use clamps or screws for permanent fixtures

- Consider rubber padding to prevent table damage

- Check for proper weight distribution to avoid tipping

Troubleshooting Common Issues

1. Weak Prints or Breaking Parts

- Increase infill percentage and wall thickness

- Use stronger filament like PETG or Nylon

2. Print Warping or Poor Adhesion

- Use a heated bed and adjust temperature settings

- Enable brim or raft for better bed adhesion

3. Misaligned or Loose Fittings

- Adjust tolerance settings in your slicer for better fitment

- Consider adding screw holes for secure attachment

Best Places to Find 3D Models for Table Mounts

If designing from scratch isn’t an option, check out these platforms:

- Thingiverse (Large collection of free designs)

- Cults3D (Premium and free STL files)

- MyMiniFactory (Curated, high-quality models)

READ MORE – Optimizing Your Monoprice Maker Ultimate 2 Model F1505 3D Printer Knob: A Complete Guide

FAQs

1. What is the best filament for a strong table mount?

PETG is the best choice due to its combination of strength, durability, and ease of printing.

2. How much weight can a 3D-printed table mount hold?

The weight capacity depends on material, infill density, and design, but properly printed PETG mounts can hold up to 5-10 kg.

3. Do I need support when printing a table mount?

Yes, supports are often needed for overhanging or bridging sections to ensure a successful print.

4. How can I improve the durability of my table mount?

Use higher infill, thicker walls, and stronger materials like PETG or Nylon. You can also reinforce the mount with metal inserts.

5. Can I 3D print a clamp-style table mount?

Yes! Many designs incorporate clamping mechanisms that allow the mount to be securely attached to tabletops.

Concultion:

3D printing a table mount is a reasonably cheap, tailored option that enhances workspace organization and ergonomics. Selecting appropriate materials, adjusting print settings, and using correct assembly techniques will help you to produce a strong and dependable mount fit for your particular requirements. This book offers all the information you need to succeed whether your design is from scratch or using pre-made STL files.